Choosing the correct ring gasket profile is a precise step for maintaining pressure integrity in oil, gas, petrochemical, and refinery equipment. The right selection prevents leaks, preserves flange faces, and keeps operations safe. The process requires a clear evaluation of flange type, service pressure, and operating conditions. A well-matched profile allows pipelines, valves, and vessels to remain secure during continuous duty.

Profile choice also affects maintenance cycles, downtime, and the reliability of entire systems. RTJ Gaskets provide strong metal-to-metal contact for high-pressure and temperature duties, making them effective for critical service lines. A profile that seats correctly in the groove keeps the seal tight and repeatable. This attention to detail results in predictable plant performance and fewer disruptions.

Understand Metal-to-Metal Seal Needs

A metal-to-metal seal is the basis of a reliable joint. The gasket must fit into the groove with precision so that compression loads are evenly distributed. A correct fit prevents leaks during pressure cycles and thermal shifts. This keeps equipment safe and compliant with process requirements.

The gasket material must also match the hardness of the flange. A slightly softer ring gasket protects the flange face while maintaining structural integrity under load. This selection preserves the surface condition of the groove and reduces repair work. Proper material pairing adds years to the service life of the connection.

Match Profile To Flange Type

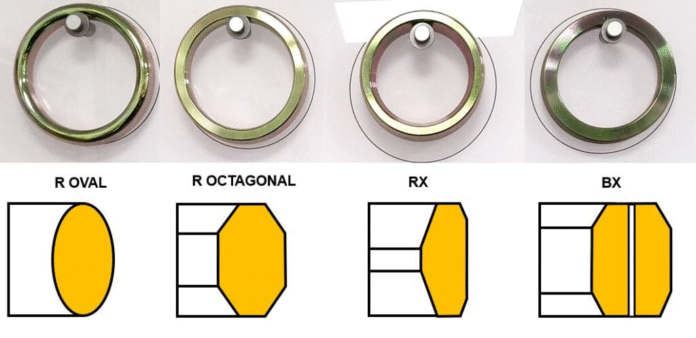

Every flange has a unique groove shape that requires an exact profile. R-type profiles are suitable for standard service, while specialized designs suit higher pressures or special media. Proper profile-to-flange matching prevents misalignment and keeps bolt loading consistent. This step supports a strong, even seal across the connection.

Following established dimensional standards makes selection easier. Maintenance teams can replace gaskets quickly during shutdowns because dimensions remain consistent across manufacturers. A correct match improves safety and lowers the risk of costly sealing failures.

Evaluate Pressure Rating For R Type

R-type profiles are offered in oval and octagonal cross sections, and each suits a different requirement. Oval sections are easier to fit, while octagonal sections offer slightly better sealing for higher pressure. Selecting the right type depends on the pressure class and groove style of the flange.

The chosen profile must hold at the maximum system pressure without distortion. Reviewing design pressure data before installation avoids blowout and system failure. A proper selection secures the joint and keeps process fluids contained. This attention to rating helps maintain safe, continuous production.

Select BX Or SBX For High Pressure

BX and SBX profiles are engineered for very high-pressure service. These precision profiles fit tightly in the flange groove and resist separation even under extreme load. They are widely used in wellheads, drilling systems, and subsea equipment where absolute sealing is required.

Choosing BX or SBX profiles gives added reliability to systems where leakage cannot occur. Their high strength reduces the frequency of replacement and extends maintenance intervals. This selection supports uninterrupted production and protects high-value equipment from damage.

Use RX For Vibration Shock Load

Connections exposed to vibration or sudden load shifts require a profile that remains tight. RX profiles provide a pressure-activated seal that becomes tighter as internal pressure increases. This feature keeps the joint secure during fluctuating operating conditions. RX profiles are ideal for pipelines and equipment subject to continuous movement.

They also protect flange faces from wear by holding their position during stress. This benefit extends the life of both the ring gasket and flange. Selecting RX profiles helps maintain equipment reliability where mechanical forces are frequent. Plants use them to prevent costly unplanned maintenance.

Choose Rubber Coated Profile For Protection

Rubber-coated profiles are ideal for systems where flange face protection is necessary. The coating shields the surface from scratches or scoring during installation and removal. This choice is practical in units with frequent disassembly cycles. The flange remains smooth and ready for reuse, lowering repair costs.

These profiles also create a seal at lower bolt torque, which helps when heavy tightening is not possible. Lower stress on the flange reduces distortion and prolongs its life. Rubber-coated profiles support quick assembly during planned maintenance and keep sealing performance consistent.

Assess Kammprofile For Heat Exchanger Use

Kammprofile gaskets are used in heat exchangers where thermal cycles are common. Their serrated metal core, combined with a soft facing, maintains a tight seal even when flanges expand and contract. This property prevents leaks during temperature changes and pressure variations.

The design combines metal strength with the recovery ability of soft material. This allows the gasket to adapt to flange movement without losing tightness. Plants rely on this profile for long-term service in exchangers where reliability is essential. It keeps equipment productive through many operational cycles.

The selection of the proper ring gasket profile maintains safety, pressure control, and operational stability in oil, gas, petrochemical, and refinery systems. Each profile offers a unique solution for specific flange designs and service conditions. The use of RTJ Gaskets guarantees that sealing performance matches high-pressure and temperature requirements. Correct selection supports reliable production, fewer shutdowns, and long equipment life across critical process units.