In the industrial equipment manufacturing sector, maintaining high quality standards is not just a priority but a necessity. Quality control (QC) ensures that products meet rigorous safety, reliability, and performance standards before they reach the market. Implementing effective QC practices is crucial for manufacturers who aim to build trust with customers, reduce waste, and avoid the costs associated with product failures.

This article explores the best practices in QC within this industry. It will focus on the role of components such as nutserts in ensuring equipment integrity. These components are integral parts of intricate systems, ensuring seamless operation and optimal performance across diverse industries.

Establishing a Comprehensive QC Framework

The primary step is to establish a comprehensive QC framework that integrates with every stage of the production process. This framework should include detailed standards and specifications for every product, from raw materials to the final outputs. Key elements of a robust QC framework include:

- Setting clear objectives that align with customer expectations and regulatory requirements.

- Implementing rigorous testing protocols at various stages of production to identify defects early.

- Training employees on quality standards and the importance of their role in maintaining them.

- Continuous monitoring and auditing of the manufacturing processes to ensure adequate compliance and identify areas for improvement.

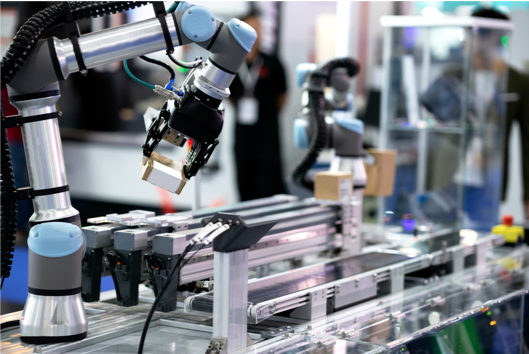

Leveraging Technology for Enhanced Quality Assurance

Technology plays a crucial role in modern QC systems. Advanced software and automation can significantly enhance the precision and efficiency of QCs. For instance, automated inspection systems equipped with high-resolution cameras and sensors can help detect minute anomalies that human inspectors might miss. Similarly, implementing enterprise resource planning (ERP) systems can help manage quality data effectively, facilitating quicker decision-making and better product traceability.

Importance of Supplier Quality Management

The quality of the final product is often as good as the quality of the materials used. Therefore, establishing strict criteria for suppliers is essential. Supplier quality management practices include:

- Conducting thorough audits and assessments of suppliers to ensure they meet the required standards.

- Engaging in partnerships rather than transactional relationships with suppliers to foster better quality improvements.

- Implementing traceability systems to track the quality of materials from the supplier to the finished product.

Ensuring Reliability in Fastening Solutions

Nutserts, a threaded insert for creating strong threads in thin or brittle materials, are crucial in many industrial applications. These components are particularly valuable when high strength is needed, but traditional nuts and bolts cannot be used due to design constraints. Here are a few ways in which quality control is particularly important:

Material quality: They must be made from high-quality materials to withstand the forces they will be subjected to during application. This requires selecting the right manufacturers and suppliers who use precise material selection and treatment processes.

Dimensional accuracy: Given that nutserts are used in applications requiring exact fits, the dimensional accuracy of these components is non-negotiable. Even slight deviations can lead to assembly issues or failures in service.

Installation reliability: QC doesn’t stop at production; it also involves ensuring that products can be consistently and reliably installed. This might involve training technicians and regular audits of installation processes.

Creating a Culture of Quality

Ultimately, the effectiveness of QC practices depends significantly on the organisational culture. A culture that values quality and continuous improvement encourages employees at all levels to take ownership of QC. This can be fostered by:

- Recognising and rewarding quality achievements to motivate staff.

- Encouraging open communication about issues without fear of reprisal.

- Investing in ongoing training and development to keep skills relevant and up-to-date.

Quality control in industrial equipment manufacturing is complex and multifaceted, requiring attention to detail, rigorous standards, and a proactive approach to managing potential issues. Manufacturers can ensure their products consistently meet or exceed expectations by adopting best practices such as paying particular attention to critical components like nutserts. Ultimately, the goal is to build a reputation for reliability and excellence that stands the test of time, thereby securing the trust and loyalty of customers globally.