Custom special effects printing trends are changing how printed designs are made to stand out. These effects give materials more shine, texture, and depth. They are used in packaging, marketing, and other printed products to grab attention.

Businesses use them to make their items look unique and more valuable. Printing technology now makes these styles easier to produce. More options mean it is possible to match any brand style or project need.

The sections below show how custom special effects printing trends are shaping the printing industry today.

Rise of Metallic and Foil Finishes

Metallic and foil finishes add a shiny reflective look that makes prints feel premium. They are often used to highlight key areas such as logos, borders, or text. The contrast they create works well in both light and dark designs.

These finishes are common in packaging, invitations, and promotional pieces where a high-end look is important. They hold visual interest and can help products appear more valuable. More businesses are now using them as printing technology becomes more cost-effective.

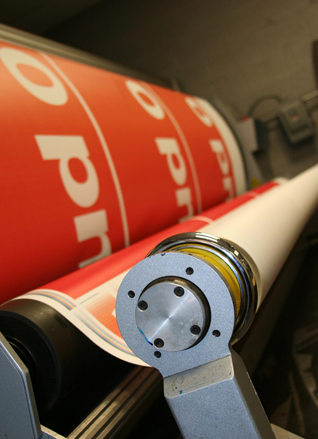

Textured Printing for Added Dimension

Textured printing adds a touchable layer to designs that makes them feel more engaging. Raised ink, embossing, and similar effects give materials depth and structure. This style works for packaging, business cards, and marketing pieces that aim to make a strong first impression.

Texture can draw attention to certain details in a design. It also gives prints a more memorable quality for the person holding them. High-quality customizable special effects printing often uses these textures to make products unique.

UV Spot Coating for Visual Focus

UV spot coating is a finish that makes selected areas of a design glossy and noticeable. It works best for logos, main images, or specific words that need to stand out. The shiny coating contrasts well with matte areas of a print.

This effect draws the eye toward the most important parts of the design. It is popular for brochures, flyers, and packaging that need a modern and sharp look. Many brands use it to give printed materials a polished finish.

Gradient and Color Shift Effects

Gradient and color shift effects make prints look dynamic and eye-catching. The colors change slightly depending on the light or the viewing angle. This creates an interesting visual style without adding clutter to the design.

These effects are often used in packaging and event materials to make them stand out. They can be paired with other finishes for a layered look. Printing advances have made these effects more accessible for many businesses.

Glow-in-the-Dark and Fluorescent Printing

Glow-in-the-dark and fluorescent printing add a striking visual twist that works in both light and dark settings. Glow printing is ideal for low-light visibility, while fluorescent colors create bold daytime designs.

These styles are popular for themed events, promotions, and specialty products. They add novelty and excitement that gets attention. Businesses use them to stand out in markets where standard printing might go unnoticed. Their unique nature makes them a growing choice for creative projects.

Sustainable Special Effects Printing

Sustainable printing combines creativity with environmental care. Eco-friendly inks, recyclable materials, and water-based coatings are now widely available. Many businesses want the visual impact of special effects while reducing waste.

Biodegradable foils and coatings allow for this balance. These choices appeal to customers who value both style and responsibility. The trend shows that print innovation can support both design goals and sustainability.

Holographic Printing for Modern Appeal

Holographic printing creates a shifting rainbow effect that changes as it moves in the light. This finish is often linked to futuristic or luxury design styles. It is used on packaging, labels, and collectible items to grab attention.

The effect works well in both bold and minimal designs. Printing improvements have made it more cost-effective than in the past. This has helped more brands use it to stand out.

Matte and Soft-Touch Finishes

Matte and soft-touch finishes create a smooth, non-reflective surface with a refined feel. The soft-touch coating adds a velvety texture that feels premium. These finishes are used on packaging, marketing pieces, and business cards.

They protect prints from scratches and fingerprints while enhancing appearance. They can also be combined with glossy or metallic details for contrast. This style gives a modern and professional look to printed work.

Transparent and Clear Printing Effects

Transparent and clear printing blends the design into the surface underneath. It works well on glass, acrylic, and certain plastic materials. This style creates a subtle but polished appearance.

Clear ink can be layered to add depth without overpowering the design. It is popular for minimalist branding and packaging. When combined with other effects, it can make the final result even more striking.

Raised UV Printing for Impact

Raised UV printing makes certain parts of a design stand out in both look and feel. The raised surface creates a clear texture difference from the rest of the print. It works for logos, lettering, and patterns that need extra emphasis.

The finish is durable and can be applied to many materials. This style makes printed designs more engaging for the person holding them. It is a strong choice for businesses that want a lasting impression.

Pearlescent and Shimmer Coatings

Pearlescent and shimmer coatings add a soft glow that catches light in a subtle way. They create a gentle shine without being overly bright. These finishes are used for invitations, packaging, and decorative items.

The shimmer can be adjusted for a more muted or more noticeable effect. They pair well with delicate designs and light color palettes. This makes them a preferred choice for special events or seasonal products.

Heat-Sensitive Color Changing Prints

Heat-sensitive printing changes colors when touched or exposed to warmth. It adds an interactive feature that makes prints fun and engaging. This style is used for promotional items, packaging, and novelty goods.

The color change can reveal hidden messages or patterns. New printing methods have made the colors more vibrant and long-lasting. It is a creative way to make products more memorable.

Discover Custom Special Effects Printing Trends in the Printing Industry

Special effects printing offers many ways to make designs stand out. From bold metallics to subtle shimmers, there are styles for every type of project. These effects can give materials a unique look while supporting branding goals.

Advances in printing technology continue to make them more accessible. Businesses that use these finishes can create stronger visual impact. Choosing the right style can help printed materials be more engaging and memorable.

For more topics, visit our blog page. We do have more!