When it comes to automotive engines, few components are as critical — or as complex — as the cylinder head. Sitting at the top of the engine block, the cylinder head plays a crucial role in controlling airflow in and out of the combustion chamber, facilitating fuel delivery, and managing exhaust. Without a properly functioning cylinder head, an engine’s efficiency, performance, and reliability can suffer dramatically.

Whether you’re a car enthusiast, a professional mechanic, or simply someone looking to better understand the inner workings of your vehicle, this complete guide to cylinder heads will help you grasp everything you need to know about this essential engine component.

What Is a Cylinder Head?

At its core, the cylinder head is the crowning piece that seals the top of the engine’s cylinders. It creates the combustion chamber, holds key components like the intake and exhaust valves, spark plugs, and fuel injectors, and facilitates the intake of air and fuel while managing the exit of exhaust gases.

Cylinder heads must be engineered to withstand extreme conditions, including high temperatures, intense pressure, and constant mechanical movement. Typically, they are made from either cast iron or aluminum alloys, depending on the needs of the engine — durability for heavy-duty engines or lighter weight for performance engines.

Key Functions of a Cylinder Head

The cylinder head performs several vital roles:

- Sealing the Combustion Chamber: Together with the head gasket and engine block, it creates a sealed space for combustion.

- Housing Valves and Components: Intake valves allow air and fuel to enter the combustion chamber, while exhaust valves let spent gases exit.

- Managing Airflow: The design of the intake and exhaust ports is critical for optimal engine breathing and performance.

- Cooling and Lubrication Channels: Built-in channels circulate coolant and oil to regulate temperature and minimize wear.

- Fuel and Ignition: It often houses the spark plugs (for gasoline engines) or fuel injectors (in diesel engines).

Types of Cylinder Heads

Different engine designs call for different types of cylinder heads:

- Flathead: An older design where the valves are located beside the cylinder rather than above it. Simple but inefficient by today’s standards.

- Overhead Valve (OHV): The valves are placed directly in the head, and pushrods operate them via a camshaft located in the engine block.

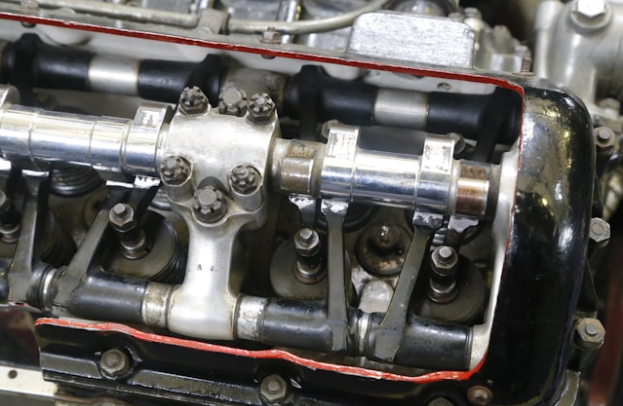

- Overhead Camshaft (OHC): The camshaft is located inside the cylinder head, providing more precise timing and better performance.

- Dual Overhead Camshaft (DOHC): Two camshafts per cylinder head (one for intake valves, one for exhaust valves), allowing for even finer control and higher performance, especially in multi-valve designs.

Understanding which type of cylinder head your engine uses can inform everything from maintenance schedules to performance upgrades.

Common Materials Used in Cylinder Heads

Cylinder heads are typically made from:

- Cast Iron: Very durable and resistant to warping. Ideal for heavy-duty engines but heavier than aluminum.

- Aluminum: Lighter and provides better heat dissipation, making it a popular choice for modern performance vehicles.

Each material comes with its trade-offs. Cast iron heads are strong and long-lasting but add weight, while aluminum heads enhance performance but can be more prone to damage if overheated.

Signs of Cylinder Head Problems

A failing or damaged cylinder head can lead to serious engine issues. Here are common signs to watch out for:

- Engine Overheating: A crack in the cylinder head can cause coolant loss or improper circulation, leading to overheating.

- Poor Engine Performance: Loss of compression can reduce engine power and efficiency.

- White Smoke from the Exhaust: This could indicate coolant leaking into the combustion chamber.

- Oil Contamination: A cracked head can cause oil and coolant to mix, leading to milky oil.

- Misfires and Rough Idling: Poor sealing can cause incomplete combustion, leading to misfires.

Addressing these symptoms early can prevent more extensive and costly engine repairs.

Cylinder Head Maintenance and Repair

Keeping your cylinder head in top condition involves regular maintenance practices:

- Check Coolant Levels: Low coolant can lead to overheating, which damages the head.

- Monitor Oil Condition: Milky or foamy oil is a red flag that should be investigated immediately.

- Follow Proper Torque Specifications: When replacing the head gasket or reassembling the engine, tightening bolts in the correct sequence and to the correct torque is critical to avoid warping.

- Flush the Cooling System: Prevent blockages and corrosion by flushing the system according to your manufacturer’s recommendations.

In cases where damage occurs, cylinder heads can sometimes be resurfaced or welded, but replacement might be necessary for severe cracks or warping.

Upgrading Cylinder Heads for Performance

For performance enthusiasts, upgrading the cylinder head can yield significant horsepower and torque gains. Popular upgrades include:

- Porting and Polishing: Smoothing the intake and exhaust ports to improve airflow.

- Installing Larger Valves: Allows more air and fuel into the combustion chamber for increased power.

- Aftermarket Heads: Companies offer high-performance cylinder heads designed for better airflow, lighter weight, and improved combustion efficiency.

Choosing the right upgrade depends on your goals — street performance, racing, or towing — and your budget.

Innovations in Cylinder Head Design

Modern technology continues to push the boundaries of cylinder head performance. Some innovations include:

- Variable Valve Timing (VVT): Adjusts the timing of valve opening and closing for better efficiency and power across a wider RPM range.

- Direct Injection Systems: Modern heads are often designed to work with direct injection, placing the injector directly into the combustion chamber for improved fuel efficiency.

- Multi-Valve Configurations: Four-valve-per-cylinder designs (two intake, two exhaust) are now common, providing better breathing and more power.

Manufacturers are constantly exploring materials like carbon composites and advanced alloys to make cylinder heads even lighter, stronger, and more thermally efficient.

Conclusion

The cylinder head is truly the heart of your engine’s breathing system. It is responsible for everything from controlling airflow and combustion to maintaining efficiency and ensuring power output. Understanding its role, construction, maintenance needs, and potential for performance enhancement is essential for anyone serious about automotive care or performance tuning.

Whether you’re troubleshooting an engine issue, considering a performance upgrade, or simply curious about how your car works, knowing about cylinder heads offers invaluable insight into the very core of automotive engineering.

If you want to dive deeper into real-world applications, performance parts, or repairs, places like Behind The 8 offer a wealth of knowledge and resources to enthusiasts and professionals alike.

Cylinder heads may seem intimidating at first, but once you understand their importance and function, you’ll gain a deeper appreciation for the engineering marvel that powers your vehicle every day.