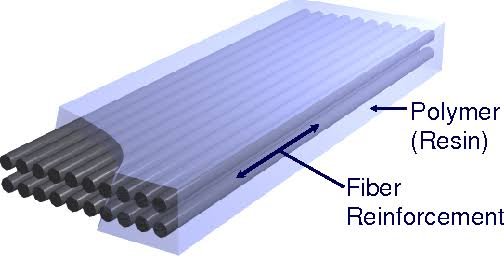

Fiber-reinforced plastic composites are materials widely used across multiple industries. These composites combine the flexibility of plastic with the strength of fibers, creating a versatile, durable solution for various applications. The combination of these two components results in a material that is both lightweight and robust. Companies have increasingly turned to these materials due to their ability to offer superior performance in diverse conditions.

Fiber-reinforced plastic composites by brands like ryertex are particularly valued for their balance of strength and weight. Manufacturers and service providers alike are exploring the full range of benefits these materials offer. This article outlines the key advantages these materials bring to different sectors.

Superior Strength-to-Weight Ratio

Fiber-reinforced plastic composites offer a significant strength-to-weight advantage. They are much lighter than metals, yet they maintain a comparable, or even superior, level of strength. This quality is essential in industries like aerospace and automotive, where reducing weight without compromising strength is a priority. The lower weight contributes to fuel efficiency in vehicles, reducing operating costs and environmental impact over time.

The material’s ability to maintain structural integrity while remaining lightweight makes it ideal for high-performance applications. Many manufacturers rely on this combination to improve the efficiency of their products and reduce energy consumption in transportation and other industries.

Enhanced Durability and Longevity

Durability is one of the primary benefits of fiber-reinforced plastic composites. These materials are resistant to wear, making them suitable for demanding applications. For instance, in construction and heavy machinery, components made from these composites are less likely to degrade. This results in long-term cost savings for businesses that use these materials in their products or infrastructure.

Fiber-reinforced plastics are also resistant to many environmental factors that typically affect other materials, such as rust or corrosion. Their longevity in challenging conditions helps companies minimize maintenance and repair costs, ensuring the performance of their products over time. Manufacturers appreciate these materials for their ability to withstand prolonged exposure to elements without losing their effectiveness.

Resistance to Corrosion

One of the standout features of fiber-reinforced plastic composites is their resistance to corrosion and chemicals. These composites do not degrade when exposed to moisture or harsh chemicals. This makes them an ideal choice for industries like marine, chemical processing, and food production, where components must endure corrosive substances.

The corrosion resistance of these materials means that products made from fiber-reinforced plastics require less maintenance, reducing operational downtime. Whether used in pipelines, tanks, or processing equipment, these composites help ensure that machinery and structures last longer. Their ability to resist corrosion extends the lifecycle of products, offering both financial and operational benefits to companies.

Versatile Capabilities

Fiber-reinforced plastic composites provide significant flexibility in design. This flexibility is valuable in industries such as automotive manufacturing, where components must meet specific design criteria while maintaining strength and durability. The ability to mold these materials into complex shapes without compromising performance makes them highly attractive to designers and engineers.

Fiber-reinforced composites can be tailored to meet specific performance needs by adjusting the type and amount of fibers used. For example, adding carbon fibers can enhance the material’s stiffness and strength, while glass fibers may improve flexibility. This versatility allows manufacturers to create customized solutions for their products.

Environmental Impact Reduction

Using fiber-reinforced plastic composites can help reduce environmental impact. These materials are lightweight, which results in less energy consumption during transportation and production. Their extended lifespans mean fewer resources are needed for replacements, reducing waste over time. As businesses increasingly seek ways to improve sustainability, fiber-reinforced plastics provide a practical solution for reducing the environmental footprint of manufacturing processes.

Companies also have the option to use recycled fibers in the production of these composites. This not only reduces the demand for new raw materials but also contributes to a more sustainable supply chain. With growing concerns over environmental sustainability, many manufacturers are turning to these eco-friendly alternatives to meet both their performance and environmental goals.

Excellent Insulation Properties

High-quality fiber-reinforced plastic composites from brands like ryertex offer excellent insulation properties, both thermally and electrically. This makes them ideal for use in applications that require protection from heat or electricity. These materials are commonly used in electronics, construction, and automotive industries, where insulation is necessary to ensure safety and maintain efficiency.

These composites also have a high resistance to fire, adding an extra layer of security in environments where fire resistance is critical. For example, in the construction of buildings or electrical systems, fiber-reinforced plastics provide the necessary insulation to prevent heat transfer. Their insulating properties make them a reliable option for various industries seeking enhanced safety and performance.

The benefits of fiber-reinforced plastic composites are significant and diverse. These materials offer a unique combination of strength, durability, and lightweight properties that make them an ideal choice for many industries. Companies that use these materials gain advantages in terms of cost, efficiency, and long-term performance.